Rubber Damper

After 30 years, five locations, and three generations of hard work, ZLR successfully maintained the core values established in 1993 with a full commitment to employees, customers, and the community.

Description

Introduction to Custom Made Rubber Vibration Damper

Custom made rubber dampers are precision-engineered vibration isolation components designed to meet the unique specifications of various industries and applications. Unlike standard rubber dampers, these are tailored to fit specific dimensions, shapes, and operational requirements, ensuring optimal performance and compatibility in noise and vibration reduction.

Material Composition

– Natural Rubber (NR): Known for its excellent elasticity and resilience, providing superior damping characteristics.

– Butyl Rubber (IIR): Offers excellent impermeability to gases and resistance to weathering, making it ideal for outdoor applications.

– Ethylene Propylene Diene Monomer (EPDM): Provides good resistance to heat, weathering, and ozone, suitable for a wide range of environmental conditions.

– Silicone: Known for its high-temperature resistance and flexibility, useful in applications requiring a wide temperature range.

Damping Capability

– Frequency Range: These rubber dampers can effectively absorb vibrations across a broad frequency spectrum, ensuring consistent performance in various environments.

– Durability: Designed to withstand long-term exposure to mechanical stress without significant loss of performance.

Customization Options

– Dimensions: Available in a range of sizes to fit the exact requirements of the application, from compact to large-scale dampers.

– Shapes: Besides standard cylindrical and rectangular, custom shapes can be manufactured to suit specific mounting configurations or complex structures.

– Damping Force: The damping force can be adjusted to meet the demands of the application, affecting its vibration isolation efficiency and resistance to fatigue.

Manufacturing Process

– Molded to Order: Each rubber damper is crafted using precision molding techniques to ensure a perfect fit and consistent quality.

– Quality Assurance: Rigorous testing and inspection processes are employed to guarantee the dampers meet the highest quality standards.

Applications

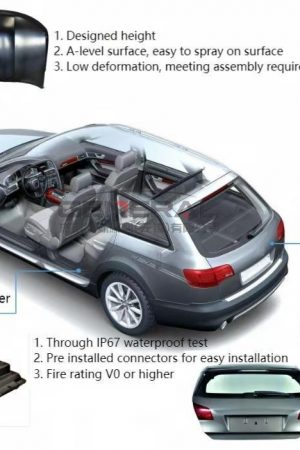

– Automotive: Used in engine mounts and suspension systems to reduce vibrations and enhance ride comfort.

– Industrial Machinery: Ideal for isolating vibrations in heavy machinery and equipment, protecting sensitive components and reducing noise pollution.

– Building Structures: Utilized in isolating vibrations from construction activities or seismic events, ensuring structural integrity and safety.

Performance Features

– Vibration Absorption: Exhibits high performance in absorbing vibrations, reducing noise and improving the stability of equipment.

– Temperature Resistance: Maintains its properties under a wide range of temperatures, suitable for both indoor and outdoor applications.

– Load Bearing Capacity: Designed to handle varying loads, ensuring reliable performance under different operating conditions.

Advantages Over Standard Rubber Dampers

– Precision Fit: Custom dimensions ensure optimal vibration isolation and maximum comfort.

– Longevity: Engineered to withstand the rigors of continuous mechanical stress, extending the service life of the damper.

– Versatility: Can be tailored to meet a wide range of industry-specific requirements, including specific environmental conditions.

Technical Specifications

– Sizes: Customizable to fit any application, accommodating both metric and imperial measurements.

– Material Properties: Detailed chemical and physical properties, including tensile strength, elongation at break, and specific gravity.

Customization Services

– Consultation: Our team of experts is available for consultation to understand your specific needs and recommend the best solution.

– Design Assistance: We offer design support to create a custom rubber damper that integrates seamlessly with your equipment and processes.

Contact Us

For more information on our custom made rubber dampers or to discuss your specific requirements, please feel free to reach out to our dedicated customer service team. We are committed to providing you with the highest quality vibration isolation solutions tailored to your needs.

If you need rubber vibration damper manufacturing, look for ZLR. Our high quality dampening rubber products for sale can meet various customer needs.

https://www.allaboutrubber.com/Custom-Nitrile-Rubber-Gasket-Manufacturer.html

Reviews

There are no reviews yet.