Oblique Cut Lamination

Shearing is a common cutting method for silicon steel sheets. Silicon steel is sheared with a carbide blade, which can cut the required size and shape. Shear method on the thermal impact of silicon steel core is small, the kerf is smoother, but the shear force is more damage, easy to produce deformation and burr. Therefore, the shear method is suitable for cutting smaller lamination, the requirement of surface flatness is not too high occasions.

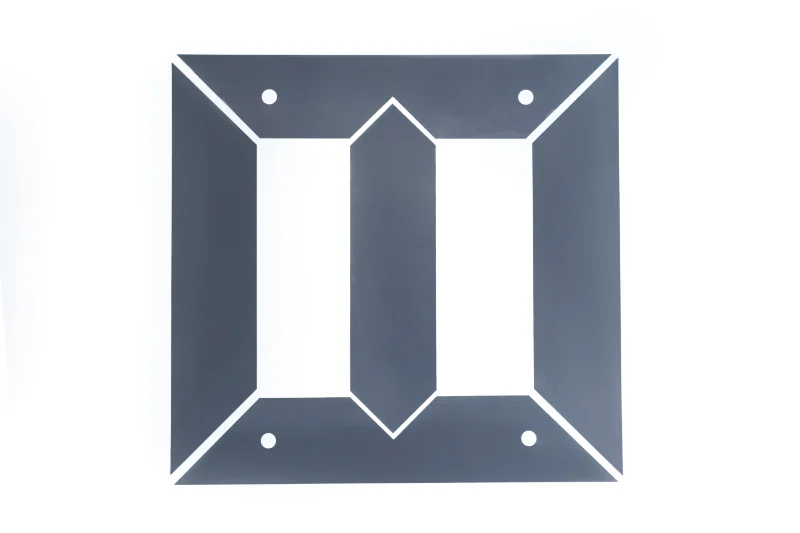

Our company has introduced advanced oblique cut equipment, which is able to cut large silicon steel core to meet more needs of customers.

Description

In the realm of electrical engineering, the performance of transformers and motors hinges on the quality of their core components. Jiangyin Tianxiang Electrical Appliance Co., Ltd. specializes in the manufacturing of oblique cut silicon steel lamination, a superior material that is pivotal to the efficiency and reliability of electrical devices.

Silicon steel, an alloy known for its magnetic properties, is a cornerstone in the construction of transformer cores and motor laminations. The oblique cut silicon steel lamination produced by our company is sheared with precision using carbide blades, ensuring a clean cut that meets the required size and shape specifications. This method is particularly advantageous due to its minimal thermal impact on the silicon steel core, resulting in a smoother kerf and less material distortion.

However, it is important to note that the shearing force in this method can potentially cause deformation and burr if not executed with the utmost care. To mitigate this, Jiangyin Tianxiang Electrical Appliance Co., Ltd. has adopted advanced oblique cutting equipment, which allows us to cut large silicon steel cores with the precision and quality needed for more demanding applications.

As a leading oblique cut silicon steel lamination manufacturer, we take pride in our ability to meet the diverse needs of our customers. Our product range is tailored to accommodate various industrial requirements, ensuring that our clients receive the most suitable solutions for their electrical devices.

The Benefits of Oblique Cut Silicon Steel Lamination

The oblique cut silicon steel lamination offers a range of benefits that make it an ideal choice for electrical applications:

-

Reduced Eddy Currents: By using laminated silicon steel, we effectively reduce eddy currents, which are induced in solid conductors by changing magnetic fields. This reduction leads to an increase in the power output of motors and a more efficient operation of transformers.

-

Lower Core Losses: The lamination process inherently minimizes hysteresis and eddy current losses, making the generation of the electromagnetic field more efficient and contributing to the overall performance of the motor or generator.

-

Enhanced Magnetic Properties: The silicon steel used in our laminations exhibits high magnetic permeability and low coercivity, allowing for efficient energy transfer and precise control in electrical devices.

-

Customizability: Jiangyin Tianxiang Electrical Appliance Co., Ltd. provides customization options for the oblique cut silicon steel lamination, ensuring that our products meet the specific dimensional and performance criteria of our customers.

-

Quality Assurance: Our commitment to quality is evident in every oblique cut silicon steel lamination we produce. We employ stringent quality control measures to ensure that each product meets industry standards and customer expectations.

Manufacturing Excellence

Established in 1990, Jiangyin Tianxiang Electrical Appliance Co., Ltd. has grown to become a reputable oblique cut silicon steel lamination supplier. Our state-of-the-art facilities house a range of high-precision and high-speed stamping machines, which, along with our team of professional management personnel, enable us to produce over 60 different series of electrical appliance components.

Our manufacturing prowess is complemented by a monthly heat treatment capacity of 600T and electromagnetic performance testing conditions, ensuring that the iron cores we produce are of the highest quality and suitable for a wide range of applications.

Product Range

Our product line encompasses a variety of iron cores, including but not limited to:

-

EI standard iron cores

-

UI type iron cores

-

Three-phase EI type iron cores

-

Linear motor iron cores

-

Sensor C iron cores

-

Small household appliance stator and rotor iron cores

-

Lamp ballast iron cores

-

TL type iron cores

-

Vehicle ignition coil cores

-

Reactor shear cores

-

EI air gap inductor cores

-

Inkjet printing micro cores

-

Contactor pull-in cores

-

Industrial electrical protector lock cores

Commitment to Innovation

At Jiangyin Tianxiang Electrical Appliance Co., Ltd., we are committed to staying at the forefront of innovation. Our investment in advanced oblique cutting equipment is a testament to our dedication to providing cutting-edge solutions to our customers. We continuously strive to improve our manufacturing processes and product offerings to meet the evolving needs of the electrical industry.

Jiangyin Tianxiang Electrical Appliance Co., Ltd. is more than just an oblique cut silicon steel lamination manufacturer; we are a partner to our customers in their pursuit of excellence. Our focus on quality, innovation, and customer satisfaction sets us apart as a leading supplier in the electrical appliance components market. Whether you require a standard product or a specialized solution, trust us to deliver the oblique cut silicon steel lamination that meets your precise requirements.

For more information on our products and services, or to discuss your specific needs with our team of experts, please do not hesitate to contact us.

Reviews

There are no reviews yet.