MA-(0.8~4MM)×1300MM Steel Coil Slitting Equipment

MA-(0.8~4MM)×1300MM Steel Coil Slitting Equipment can process the slitting of the coil with different sizes to small strips for processing various kinds of metal coil materials.

Description

https://www.mazsmachine.com/MA-0-8-4MM-1300MM-Steel-Coil-Slitting-Equipment.html

General Introduction

– MA-(0.8~4MM)×1300MM Steel Coil Slitting Equipment is designed and constructed to the highest accuracy, efficiency , automation and performance for processing various kinds of metal coil materials, processing with the slitting the coil with different size to small strips . MA-(0.8~4MM)×1300MM Steel Coil Slitting Equipment is with high precision high speed and high efficiency and high automation. This line is a light type line which has lower investment and suitable for small or middle factories who has lower budget.

Detailed Technical Data

|

NO. |

Item |

Parameters |

|

1 |

Applicable material |

Carbon steel Q195 Q235 Q345 |

|

2 |

Thickness of material |

0.8-4mm |

|

3 |

Material width |

800~1300mm |

|

4 |

Inner diameter of steel coil |

Ø480mm ~ Ø520mm |

|

5 |

Outer diameter of steel coil |

≤Ø1800mm |

|

6 |

Weight of steel coil |

20T |

|

7 |

Thickness of finished product |

0.8-4mm |

|

8 |

Inner diameter of finished coil |

Ø480mm ~ Ø520mm |

|

9 |

Outer diameter of finished coil |

≤Ø1800mm |

|

10 |

Min. slitting width |

35mm |

|

11 |

Slitting speed |

60-100m/min adjustable. |

|

12 |

Cutter knife diameter |

D250*d120*T10 |

Machine Main Components

– Feeding trolley – single-arm feeding machine, coil leading device – tilting platform – looper 1 – rectification – disc shear – waste scrap winding – looper 2 – pre-slitting, tension machine, length measuring roller – recoiling – unloading trolley – hydraulic control – electrical control

Production Line Flowing Chart

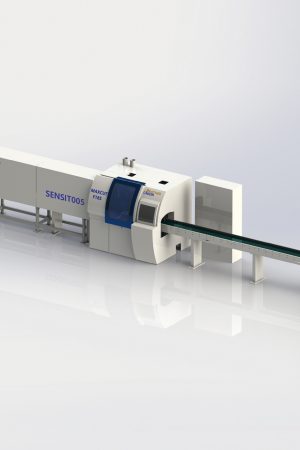

Machine Photo for Reference

Loading and Packing

Machine will be fixed inside container by steel wire and special PET strap to be , in order to make sure all parts will not move during transportation and avoid any kinds of damage of machine and container.

Why choose MAZS?

– Our Production Capacity

Wuxi MAZS Machinery Science & Technology Co., Ltd. is a manufacturer specializing in the design and manufacture of cold rolling mills, slitting production lines, cross-cutting production lines, and high-frequency welded pipe unit production lines. It has advanced design concepts, rich production experience, and perfect product quality management. , the most competitive price, and excellent after-sales team service are the cornerstones of our long-term foothold and development in the equipment manufacturing industry of the construction machinery industry.

– Inspection

Before the products leave our factory, MAZS company conducts the following inspection work and provides relevant product inspection standards and specifications to relevant technical personnel.

The product has strict quality management control process in each production link.

Excellent industrial workers can make qualified products.

– Training

In order to enable users to better operate, maintain and manage the equipment, MAZS company will arrange experienced installation and commissioning engineers to conduct installation and commissioning training and guidance. The company can provide customers with in-factory training and on-site training in two ways for users' option.

– Installation

MAZS company arranges engineering and technical personnel with rich installation experience to go to the site for installation guidance.

MAZS company arranges technical personnel with installation experience and excellent business skills to go to the site to carry out equipment installation and trial operation with relevant engineering personnel and submit production data if necessary.

After the customer's acceptance, Wuxi MAZS Co., will provide life-long after-sales service (including maintenance, maintenance, repair, wearing parts, etc.) for the product.

Reviews

There are no reviews yet.