Electronic Ignition Exothermic Weld 2.0 Wholesale And Factory Price (IEEE837,UL,IEC,ROHS)

Electronic Ignition Exothermic welding 2.0(E-Plus2.0) is the latest generation of Sunlightweld.Compared with traditional exothermic weld,it’s more cost-saving, environmental-friendly, user-friendly.

Description

Electronic Ignition Exothermic Welding 2.0 (E-PLUS 2.0)Advantages When Compared to Similar Brands

Electronic ignition exothermic welding 2.0(E-PLUS 2.0) manufactured by Sunlightweld factory has IEEE837, UL467, IEC62561-1, and ROHs certification, The following are some typical advantages for Eplus 2.0 compared to other exothermic welding brands:

1.100% ignition rate: The flexible design for the starting module of Sunlightweld's ignition starter is not easy to shift, make sure100% ignition rate, and the ignition efficiency is consistent and stable.

2.More cost-saving:The operation time to complete the whole exothermic welding process just within seconds: Put E-plus exothermic welding cup into the graphite mold, connect the ignition wire to the welding cup, then press the switch button to perform exothermic welding. There is no need to unpack, place steel disc, sprinkle ignition powder, ignite and other operations, saving about 70% of operating time, and of course save labor cost for you.

3.SunlightWeld is much more competitive in prices: Based on China's powerful industrial system and lower labor cost, we enables our international distributors/partners to have more profit(at least 30% more). Besides, we will consistently provide help for developing your business by providing training, technical support and marketing, and we can arrange online meeting to show you around our factory and facilities in China.

https://www.sltup.com/Electronic-Ignition-Exothermic-Welding-Wholesale-And-Factory-Price.html

4. Safer operation: The electric starter comes with 1.8m wire(3m wire optional), double-switch mode, and with warning reminder function to avoid accidental injuries during exothermic welding process. Besides, completes welds at distances, avoid burns during the exothermic reaction.

5. Less residue, more environmental-friendly: The E-plus cup body is also a part of the welding formula, the whole copper cup will participate in the exothermic reaction, the cup body integrated into the welding material, there is almost no residue left.

6. Safe transportation and storage: Electronic ignition exothermic welding manufactured by our factory does not contain flammable and explosive components, no external starting power or heat source, so that can be transported by air to reduce transportation time. Moreover, 8-layer protective packaging(better packages against damping, moisture and vibration) is used to ensure the quality stability of the product under natural environment, and it is easy to store and keep.

7. Comfort Operation:

1)Safe and easy to use with minimal training and protective requirements.

2)The double switch design reduce any risk of misapplication.

3)Exothermic welding electronic starter initiates in 3 seconds with No black smoke, No pungent or toxic, and harmless to human body.

4)Sunlightweld ignition starter can work under -10°C while other competitor startr only works above 0℃+

Product Options(Customized Available)

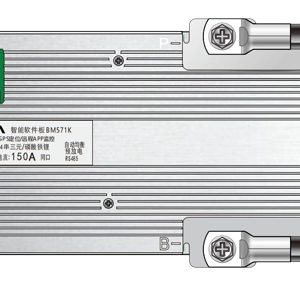

Multiple Powder choice: 45#, 65#, 90#, 115#, 150#, 200#, 250#(100% suit for market requirements)

Installation/Demonstration

Lead Time

1-2 workdays(average), within 7 workdays(for large&bulk orders)

After-sale Service(Within 24hrs)

Any product quality problems occur, our salesman and technical&product engineer will response within 24hrs

Reviews

There are no reviews yet.